Technology

ICAR – Certified Technologies

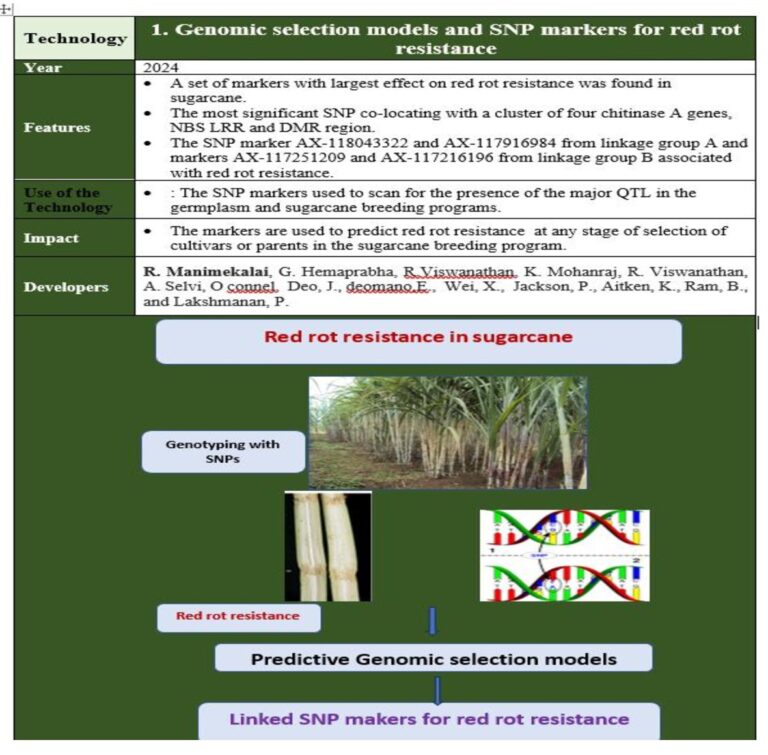

1. Genomic selection models and SNP for red rot resistance

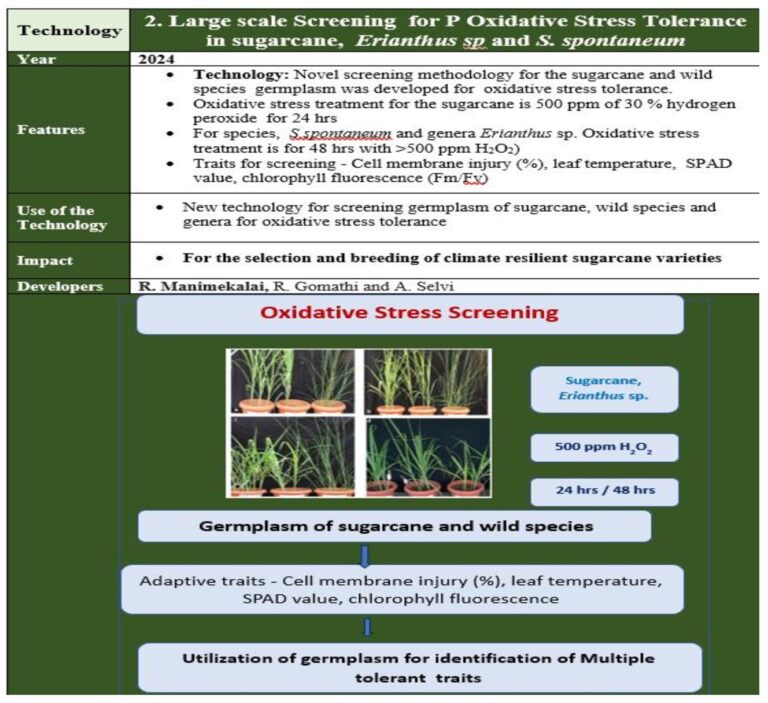

2. Screening for oxidative stress tolerance in sugarcane and wild species.

ICAR-CIAE-SBI Small tractor operated EPN applicator for sugarcane white grub management

Inventors/Developers

Dr.T.Senthilkumar and Dr.Syed Imran – ICAR-CIAE, Regional Station, Coimbatore

Dr.T.Arumuganathan, Dr.C.Sankaranarayananan and Sh. M. Rajesh Kumar – ICAR-SBI, Coimbatore

- The small tractor operated EPN applicator consists of main frame, tank holding assembly, agitator, water pump, furrow opener, standard three-point hitch and a 150-liter tank to carry the EPN solution. The tank consists of agitator and two EPN solution outlet flexible tubes. The agitator consists of two numbers of baffles at the end of vertical shaft. The agitator shaft was operated by 12 V high torque DC motor. The agitator provides continues agitation of EPN solution and avoid suspension of particles so that it results in uniform delivery of the EPN. Pumping of EPN solution was done by two numbers of 4.0 LPM / 12v DC Water Sprayer Motor Diaphragm pump.

- The developed unit was field tested at ICAR- Sugarcane Breeding Institute and M/s. Bannari Amman Sugars, Sathyamangalam. The results indicated that the EPN delivery in the right side out let was 30-35 IJs/ml and left side out let was 30-35 IJs/ml.

- The average actual field capacity is 0.18 hah-1. The cost of operation was workout as Rs. 2550 per ha and cost saving is 47% when compared to manual method of application.

Deep furrow sugarcane cutter planter suitable for tropical region

Inventors/Developers

Dr.A.K. Singh – ICAR-ISRI, Lucknow

Dr.T.Arumuganathan, Dr.Bakshi Ram, Dr. A.S.Tayade – ICAR-SBI, Coimbatore

- This deep furrow sugarcane cutter planter has been designed and developed for adjustable wide row spacing (4 feet and 5 feet) and capable for planting in heavy clayey soils in the southern states of the country.

- The cutter-planter would perform seven labour & time intensive operations in a sequence viz., opening of furrow (a groove made in the soil to plant sugarcane setts and to irrigate), cutting of sugarcane setts (sections of sugarcane stem with one or more buds), dropping of setts in the furrow, applying fertilizers, applying fungicide or insecticide solutions on the setts and soil surface, covering of setts and pressing the soil lightly.

- The planter would require 11 times less labour than the conventional method of planting, while the cost of planting could be reduced by about 53 %, using this planter. Using the machine would improve the timeliness of planting operations, reduce human drudgery and improve overall production efficiency in sugarcane agriculture.

- The machine has been demonstrated successfully in the major sugarcane growing districts of Tamil Nadu viz., Tiruvannamalai, Kallakurichi and Erode Districts.

Comercialised Technology

Soil Moisture Indicator (SMI)

Inventors/Developers

K. Hari, D. Puthira Pratap, K. Sivaraman, P. Rakkiyappan, B. Singaravelu, A. Ramesh Sundar and P. Murali

Soil Moisture Indicator is a user-friendly moisture indicating device developed by ICAR-Sugarcane Breeding Institute through ‘farmers’ participatory research. This device works based on the principle that soil electrical resistance is inversely proportional to soil moisture content. Field capacity, available soil moisture and permanent wilting point (PWP) are the key parameters considered for soil moisture indication. It works by inserting the metal rods in the soil and pressing the switch, after pressing the switch, the electronic circuit translates soil resistance into a colour glowing light emitting diode (LED). SMI will not provide the precise soil moisture status, as it is only an objective indication. SMI is portable, requires no permanent installation in the field and can be used in the field to ascertain the soil moisture level as per the user’s choice. SMI has various advantages viz., inexpensive, simple to use, no recurring expenses, relatively less maintenance, useful in subsurface drip system, irrigation water saving of about 15% and 8% improvement in cane yield. Implementation of SMI had resulted in reduction in the number of irrigations to the sugarcane crop from 42 to 36. This has helped in saving labour, electricity in sugarcane cultivation. Since it is generic in nature can be deployed in sugarcane, coconut, groundnut, mustard, brinjal, bhendi, coconut, banana, pomegranate, grapes, flowers, upland paddy, sesame, black gram, green gram, tomato etc., crops. Widespread usage of SMI in all cultivated crops would save water and other resources significantly.

IPR

One patent filed No. 2685/CHE/2010 and registered four designs (Nos 231432, 231433, 231434 and 231435); these were the first design patents registered by ICAR.

COMMERCIALIZATION

Technology has been licensed to 22 firms across the country.

SPECIAL NOTE

This technology has been included in the schemes of Department of Agriculture and farmers welfare, Government of India viz., (a) Sub Mission of Agricultural Mechanisation (SMAM), (b) National Food Security Mission (NFSM) and (c) More Crop Per Drop Scheme Per Drop More Crop of the PMKSY for water conservation with subsidy for the benefit of farmers and other stakeholders.

AWARDS

This technology bagged (1) First place in the National Water Awards – 2019, under the category “Best Research / Innovation / Adaptation of New Technology for Water Conservation” by Ministry of Jal Shakti, Department of Water Resources, River Development & Ganga Rejuvenation, Government of India and (2) First in the TERI[1]IWA-UNDP Water Sustainability Award 2021 under the category “Excellence in water use efficiency – Agricultural Sector” by The Energy and Resources Institute, New Delhi in association with International Water Association. London, United Kingdom and United Nations Development Programme, New York, USA.

Digital Soil Moisture Sensor (DSMS)

S. Anusha, K. Hari, R. Arun Kumar, C. Palaniswami, D. Puthira Prathap, B. Singaravelu, A. Ramesh Sundar, P. Murali

DSMS is an upgraded version of ICAR-SBI Soil Moisture Indicator to assess the soil moisture level at field conditions. DSMS was developed by ICAR-SBI and M/s SKR Agrotech, Nagpur through a PPP project. DSMS device is a simple, handy and IoT enabled portable device to provide quantitative level of available soil moisture as a digital display. DSMS has sensor rods which has to be inserted in the soil to know the available soil moisture level. Maintaining optimum soil moisture level is crucial by efficient irrigation management and better crop productivity. It is recommended to maintain DSMS readings of above 30% ASM and below 75% ASM most of the time. The cost of DSMS is about Rs. 3,200 (plus GST). A farmer needs only one unit for the entire field and no recurring expenses. The use of DSMS results in a saving of about Rs. 2,500 per hectare due to reduced labour and energy conservation by 250 units of electricity per year per hectare.

Model No.1- DSMS (Economic)

DSMS comprises microcontroller-based sensor rod and a casing. There are either two metal sensor rods (two individual rods spaced at distance of about 5 cm) or a combined rod. The casing houses an electronic printed circuit board with an integrated circuit, electronic components, a provision for lithium battery and a control switch. To assess the soil moisture, the stainless-steel sensor rods are to be inserted into the soil. The resistance between the sensor rods depends on the moisture content in the soil between the rods. Lower the soil moisture higher will be the resistance and vice versa. When a direct current voltage is applied between the sensor rods, there will be a voltage change in relation to the soil moisture. This altered voltage is fed to the signal input of the integrated circuit. The integrated electronic circuits translate conductivity into soil moisture content through OLED display and displays quantitative moisture percentage. The electronic circuit is designed in such a way to display moisture levels digitally. The moisture level indication will be as quantitative analysis of water holding capacity in 0 to 100 % range. A provision is given in the electronic circuit for fine-tuning the device to suit different soil conditions like sandy, clay and loamy.

Model No.2- DSMS (with GSM Module)

Similar to Model 1 but has additional feature with GSM module

COMMERCIALIZATION

This technology has been developed in partnership with M/s SKR Agrotech, Nagpur.

SPECIAL NOTE

This technology has been included in the schemes of Department of Agriculture and farmers welfare, Government of India viz., (a) Sub Mission of Agricultural Mechanisation (SMAM), (b) National Food Security Mission (NFSM) and (c) More Crop Per Drop Scheme Per Drop More Crop of the PMKSY for water conservation with subsidy for the benefit of farmers and other stakeholders.

ICAR-SBI-CIAE Sett treatment device

ICAR-SBI: P. Malathi, R. Viswanathan, P. Padmanabhan,A. Ramesh Sundar, K. Hari and V. Jayakumar

ICAR-CIAE: Ravindra Naik and Jacob Annamalai

Invention relates to new technique for the treatment of sugarcane planting material (single/ double/ triple budded setts/ bud chips) with any agrochemicals or microbes for protection from diseases / pests and improvement of plant growth. This novel technique has principle of creating negative pressure followed by absorption. This method of sett treatment is an improved method over conventional application as sett soaking at different periods of time. The setts were taken in the container having lid with connector provision for connecting tube. The suspension to be treated with the setts was prepared and added to the container till the setts were immersed in the solution. The solution can be of any agrochemicals viz., fungicide/ insecticide/ growth regulator/ adhesives/ nutrients or microbials prepared in water. The container was closed airtight with its lid and the outlet from the lid was connected to the vacuum pump. Then the vacuum was applied slowly @ 100 to 300 mmHg for 15 to 20 min. Under vacuum, it removes air in the container and setts i.e. it creates negative pressure and then the vacuum was released slowly for 5-10 minutes which led to absorption of surrounding solution inside the tissue.

IPR: A patent has been obtained for this technology No. 3323/CHE/2011 titled “Rapid treatment for planting materials of sugarcane and other vegetative propagative crops”.

COMMERCIALIZATION Technology has been licensed to 2 firms across the country.

SPECIAL NOTE This technology has been included in the schemes of Department of Agriculture and farmers’ welfare, Government of India viz., Sub Mission of Agricultural Mechanisation (SMAM)

ICAR-IISR-SBI Deep furrow sugarcane cutter planter suitable for tropical region

ICAR-CIAE: A K Singh; ICAR-SBI: T. Arumuganathan, Bakshi Ram and A.S. Tayade

Different designs of sugarcane planters have been developed by ICAR-Indian Institute of Sugarcane Research (IISR), Lucknow to mechanise the planting operation and most of the designs are suitable for sub-tropical conditions. The soil type, crop spacing, varieties and seasonal parameters are entirely different in tropical region compared to sub-tropical region. Introducing sugarcane machineries developed at ICAR-Indian Institute of Sugarcane Research, Lucknow with suitable & required modifications for the tropical conditions can certainly help the Sugarcane growers in tropical region to get the benefits of mechanization. The deep furrow sugarcane cutter planter has been designed and developed for adjustable wide row spacing (4 feet and 5 feet) and capable for doing furrow planting in heavy soils in tropical region. This will further reduce the cost of planting as well as the labour requirement for planting. Table 1 shows the various components and details of a tractor operated two row deep furrow sugarcane sett planter. Introducing this planting machinery can certainly help the sugarcane growers in tropical region to get the benefits of mechanization. There is no doubt this machinery is labour and cost saving and will make sugarcane cultivation more profitable besides reducing human drudgery.

COMMERCIALIZATION Technology has been licensed to one firm across the country.

ICAR-SBI-CIAE Sugarcane settling transplanter

ICAR-CIAE: S.J.K. Annamalai, T. Senthilkumar and Ravindra Naik ICAR-SBI: N Vijayan Nair, N. Rajendra Prasad and Bakshi Ram

A two-row tractor drawn mechanical planter for sugarcane bud chip settlings raised in protrays has been developed by ICAR-Central Institute of Agricultural Engineering, Regional Station, Coimbatore in collaboration with ICAR-SBI, Coimbatore. This tractor mounted planted considerable reduced the planting cost and resulted in good establishment of the crop. The equipment consists of mainframe to be attached to standard three point hitch arrangement of a 40 hp tractor with adjustable arrangement for altering row to row spacing 90, 120 and 150 cm. Bud chip settlings to be dropped through the metering mechanism by two operators who are seated behind the equipment with adjustable arrangements for altering plant to plant spacing of 30, 45 and 60 cm. Furrow openers open the furrow, in which the settlings with soil are to be planted with adjustable arrangement for altering depth of planting 2 to 6 cm. The same furrow is used for irrigation after the settlings have been planted for better establishment. The furrow closer which follows the soil opener closes the soil thereby giving stability to the settling plants. The field capacity of the equipment is 0.15 ha/h and the missing of 3 to 4per cent at a working speed of 1.4 km/h. The plant establishment was more than 95%. The yield and quality parameters are on par when compared with manual planting. SPECIFICATIONS OF THE MECHANICAL PLANTER Over all dimensions (l x b x h): 2400 x 2000 x 1500 mm; Weight: 590 kg; Source of power: 35 HP or above Tractor; Row spacing: 2 rows, 900, 1200, 1500 mm (Adjustable); Plant spacing in rows: 300, 450, 600 mm (Adjustable); Field capacity: 0.10 – 0.20 ha/h; Nominal working width: 1350 – 1800 mm (Adjustable); Depth of planting: 20 – 100 mm (Adjustable); Type of metering mechanism: Horizontal disc indexing mechanism; Furrow opener and closer: Shoe type furrow opener, Wheel type furrow closer; Drive mechanism: Two numbers of ground wheel for independent drive to two indexing mechanism with bevel gear box. COMMERCIALIZATION Technology has been licensed to three firms across the country.

ICAR-CIAE-SBI EPN Applicator

ICAR-CIAE: S.J.K. Annamalai, T. Senthilkumar and Ravindra Naik ICAR-SBI: N Vijayan Nair, N. Rajendra Prasad and Bakshi Ram

A two-row tractor drawn mechanical planter for sugarcane bud chip settlings raised in protrays has been developed by ICAR-Central Institute of Agricultural Engineering, Regional Station, Coimbatore in collaboration with ICAR-SBI, Coimbatore. This tractor mounted planted considerable reduced the planting cost and resulted in good establishment of the crop. The equipment consists of mainframe to be attached to standard three point hitch arrangement of a 40 hp tractor with adjustable arrangement for altering row to row spacing 90, 120 and 150 cm. Bud chip settlings to be dropped through the metering mechanism by two operators who are seated behind the equipment with adjustable arrangements for altering plant to plant spacing of 30, 45 and 60 cm. Furrow openers open the furrow, in which the settlings with soil are to be planted with adjustable arrangement for altering depth of planting 2 to 6 cm. The same furrow is used for irrigation after the settlings have been planted for better establishment. The furrow closer which follows the soil opener closes the soil thereby giving stability to the settling plants. The field capacity of the equipment is 0.15 ha/h and the missing of 3 to 4per cent at a working speed of 1.4 km/h. The plant establishment was more than 95%. The yield and quality parameters are on par when compared with manual planting.

SPECIFICATIONS OF THE MECHANICAL PLANTER

Over all dimensions (l x b x h): 2400 x 2000 x 1500 mm; Weight: 590 kg; Source of power: 35 HP or above Tractor; Row spacing: 2 rows, 900, 1200, 1500 mm (Adjustable); Plant spacing in rows: 300, 450, 600 mm (Adjustable); Field capacity: 0.10 – 0.20 ha/h; Nominal working width: 1350 – 1800 mm (Adjustable); Depth of planting: 20 – 100 mm (Adjustable); Type of metering mechanism: Horizontal disc indexing mechanism; Furrow opener and closer: Shoe type furrow opener, Wheel type furrow closer; Drive mechanism: Two numbers of ground wheel for independent drive to two indexing mechanism with bevel gear box.

COMMERCIALIZATION

Technology has been licensed to three firms across the country.

ICAR-SBI-CIAE Rind removing equipment

ICAR-CIAE: Ravindra Naik, S.J.K. Annamalai ICAR-SBI: K. Hari and Bakshi Ram

Spoilage of sugarcane juice is accelerated by presence of enzyme polyphenol oxidase in the rind of the cane, which causes oxidation of the sugars and thereby changing the colour of the juice by reacting with phenolic compounds – present in outer rind. Rind removing/ peeling enhances hygiene as it enables the removal of dirt and other unwanted particles as well as microbial load from the stalk in juice. Traditional manual method by using knife is time consuming, unsafe and unhygienic. In view of this, development of a power operated sugarcane rind removing equipment has been developed. The sugarcane rind remover consists of four metallic brushes attached to the rotating shaft. When the sugarcane is inserted between the four metallic brushes, the upper, lower and two sides skin of the sugarcane is removed due to the rotation of the brushes (because of the abrasion action between the brushes and sugarcane). The pair of metallic brushes are mounted on the shafted through the gear box so that the brushes rotate in the opposite direction at about 1050 rpm. The feeding arrangement is made of two nylon roller rotating at about 270rpm, which enables retention of the canes to be peeled for sufficient time in the peeling zone. The power transmission is through 1.5 hp single phase/ three phase motor. The equipment is mounted on the wheel enabling easy transportation from one place to another. Capacity of the power operated sugarcane rind removing equipment is 240 canes/h and 175-200 kg/h.

COMMERCIALIZATION Technology has been licensed to one firm across the country

Detrashing tool

Arumuganathan, N. Vijayan Nair, C. Palaniswami, K. Sivaraman, C. Jayabose and T. Rajula Shanthy

Detrashing in sugarcane cultivation is a recommended practice, which involves removal of unwanted bottom dried and yellowish green leaves on fifth and seventh month after planting. Though detrashing has several advantages, physical labour for doing this operation is hard to obtain because of the drudgery. When the de-trashing operation is done manually without any tool, the labourers hands are often injured and they were subjected to the “Irritant Contact Dermatitis (ICD)”, “Allergic dermatitis (AD)” and “Keratinization” (The deposition of keratin in cells occurring in the epidermis of the skin and structures in nails and hair. In view of avoiding the direct contact with hands and sugarcane leaves and also to reduce the drudgery involved in detrashing, an ergonomically improved sugarcane detrashing tool was designed and developed with a substantially reduced weight. This ergonomically improved sugarcane detrashing tool was designed for 280 g weight using the design software as against the existing model of 430 g and developed. This tool has two stainless steel (SS) knives fitted in a ‘U’ shaped stainless-steel flat with tension. These knives are 8 inches in length with varying width of 2.5 inches to 1 inch from top to bottom. The knives are welded with 4inch length stemmed 18 x 3mm stainless steel flat, which gives tension by which the knives are stiff enough to detach the leaves. At the bottom of the `U’ shaped steel flat a stainless-steel pipe of 25 mm diameter with 30 mm length is attached. It is provided with a wooden handle (1 inch diameter and 5 inches length) for convenience. An adjustable oval shaped loop of 3 mm thickness made up of SS rod was provided which can be moved to and fro to adjust the gap between two knives depending upon the diameter of the sugarcane stalk. The knives are inserted between the internodes at the top and pulled vertically down for removing the dry and unwanted leaves. Detrashing angle of 5 degree and varying approaching/ cutting width ranging from 25 to 50 mm were provided in the tool to ease the detrashing process. This ergonomically improved detrashing tool can be comfortably used for detrashing the sugarcane leaves during fifth and seventh month and the field capacity of the tool is 0.3 acre per day. COMMERCIALIZATION Technology has been licensed to two firms across the country.

Sugarcane Elevated Hybridization Runway

ICAR-SBI: N. Vijayan Nair, P. Govindaraj ICAR-CIAE: S.J.K. Annamalai and Ravindra Naik

This technology relates with an Elevated Hybridisation Runway (EHR) structure for crossing sugarcane during the hybridisation programme by ICAR- SBI, Coimbatore and ICAR-Central Institute of Agricultural Engineering – Regional centre, Coimbatore. Elevated Hybridisation Runway structure, comprises of vertically extending H shaped steel stanchion or pipes ; two levels of standing platform member attached to the main support member and extending runway structure platform at two levels generally perpendicularly, a diagonal brace member extending at an angle between the main support member and the platform member and connected at each end by means of hook attached to the platform member for limiting motion for a plank member supported on the platform member. A guard rail system is running along the scaffold structure at second working level. The platform member is attached to the main support member by means of a clamp. A set of ladder is provided to reach to the different levels of Elevated Hybridisation Runway structure. Scientists can complete all the crosses to be carried out in different rows without getting down every time since all the rows are interconnected enabling saving in time and manpower when compared to the conventional methods. The new design will facilitate large number of pollination in shorter time without losing viability of pollens which have short life period. The design is ergonomic in nature keeping the safety of operator in mind. IPR:One patent filed No. 771/CHE/2011 and registered one design No. 231436

Quatro Sugarcane Single Bud Cutter

Ravinder Kumar, M.R. Meena, N. Kulshreshtha, C. Appunu, Bakshi Ram

Quatro Sugarcane Single Bud Cutter Traditionally, sugarcane cultivation requires huge quantity of seed material nearly 7.5 to 10 t/ha, which accounts 10-15% of total the productivity. The seed multiplication rate of sugarcane is very low (1:8). Due to bulky nature of propagating material, very low average germination (35-40%), the non-uniform and inadequate germination of crop causes huge fluctuation in productivity. Planting of sugarcane crop with pre germinated settling plants is the best solution for improving seed health, seed multiplication ratio and uniformity in plant population, which ultimately assures higher sustainable crop yield. The foremost requirement of settling raising and transplanting work is the availability of cost-effective cutting tool for detaching uniform size mini single bud setts. To address this issue, ICAR-SBIRC, Karnal have designed and developed, a cost effective single budded sett cutting tool namely “Quatro Sugarcane Single Bud Cutter” which clamp. A set of ladder is provided to reach to the different levels of Elevated Hybridisation Runway structure. Scientists can complete all the crosses to be carried out in different rows without getting down every time since all the rows are interconnected enabling saving in time and manpower when compared to the conventional methods. The new design will facilitate large number of pollination in shorter time without losing viability of pollens which have short life period. The design is ergonomic in nature keeping the safety of operator in mind. IPR:One patent filed No. 771/CHE/2011 and registered one design No. 231436 Machinery / Device / Equipment Machinery / Device / Equipment 40 ICAR-SBI Technologies for Commercialization ICAR-SBI Technologies for Commercialization 41 ICAR-SBI: N. Vijayan Nair, P. Govindaraj ICAR-CIAE: S.J.K. Annamalai and Ravindra Naik ICAR-CIAE-SBI Motorised double headed sugarcane single bud cutting machine Machinery / Device / Equipment Machinery / Device / Equipment bagged design patent in the country “Design No. 297432”. Nearly 7000 to 8000 single bud setts, adequate to grow settlings for transplantation in an acre area, can effectively be detached in one hour by this machine, when it runs at full capacity i.e. four persons operating on each cutting slot of the machine. The Quatro Sugarcane Single Bud Cutter (QSSBC) was designed towards mechanization of planting operation in sugarcane. This unique design is very effective in sizing the mini setts in the form of 35 mm size (fixed size) of sugarcane single buds useful for planting in cavity trays or poly bags. In one hour four people can detach 7000-8000 single buds for raising settlings suitable for one acre. The implement runs on 1 hp power single phase motor. The maintenance is very easy. If the same work is being done by four persons using manual operator bud cutters it takes whole day. In one day (8 hours) it can detach single buds from 7-8 tonnes of sugarcane stalk. This implement is extensively used for rapid multiplication of the new varieties and improvement of seed health at ICAR-SBI Regional Centre, Karnal. To reduce volume of the seed cane material sugar mills and farmers were allowed to use QSSBC for detaching single bud setts. COMMERCIALIZATION Technology has been licensed to two firms across the country.

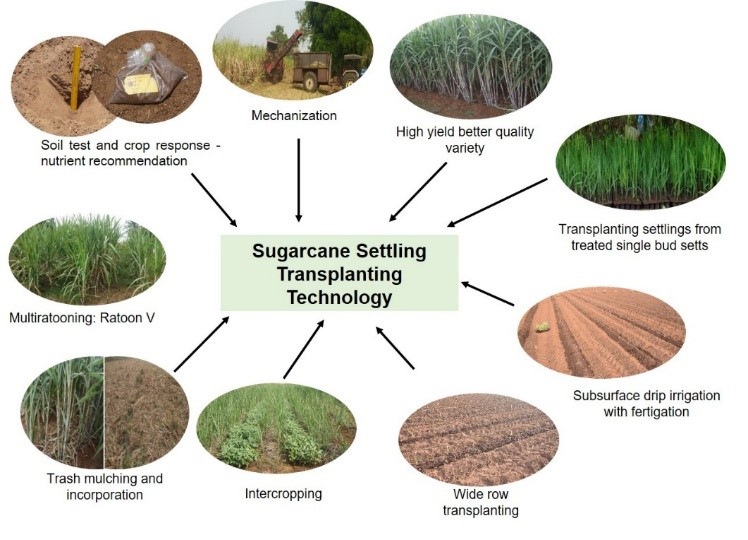

Sugarcane settling transplanting technology

- Settling Transplanting Technology (STT), an integrated approach with nine basic components ( transplanting settlings (25-30 days old) derived from single bud setts of high yielding better quality variety treated with nutrients and pesticide using Sett Treatment Device, in paired row (1.2 x 0.6/0.6 m), intercropping (black gram, green gram, coriander, etc.), sub-surface drip irrigation scheduling based on crop demand and pan evaporation and fertigation based on soil test crop response, multiple ratooning (up to 5 ratoons) and mechanization of field operations from filed preparation to harvesting) of sugarcane production aimed as a whole to reduce cultivation cost and improve productivity.

- STT as a package resulted in 80% savings in seed cane requirement and 38% savings in planting cost, savings of 52% in water, 90% labor cost for irrigation, and 50% power consumption over sett planting with furrow irrigation. Intercropping resulted in a 10-20% improvement in cane yield over sole sugarcane and provided interim and additional income. STT generated a benefit-cost ratio of 1.93 at the end of five years

- Details of Patent& Copyrights: This is a certified technology by NRM Division of ICAR (vide Certificate No. ICAR-NRM-SBI-Technology-2024-204).

Developers: A. Vennila, S. Anusha, C. Palaniswami, Bakshi Ram, P. Malathi and V. Kasthuri Thilagam

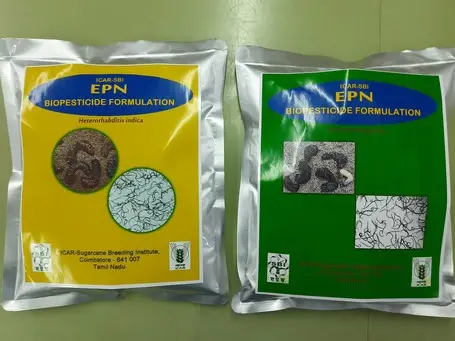

EPN TECHNOLOGY FOR MANAGEMENT OF WHITE GRUB

Inventors/Developers:

Lead:

- Sankaranarayanan Chellappa

Associates:

- Singaravelu Balasubramanian

- Rajeshkumar Muthusamy

- Nici Ashok

- Hari Kuppusamy

Technologies Details

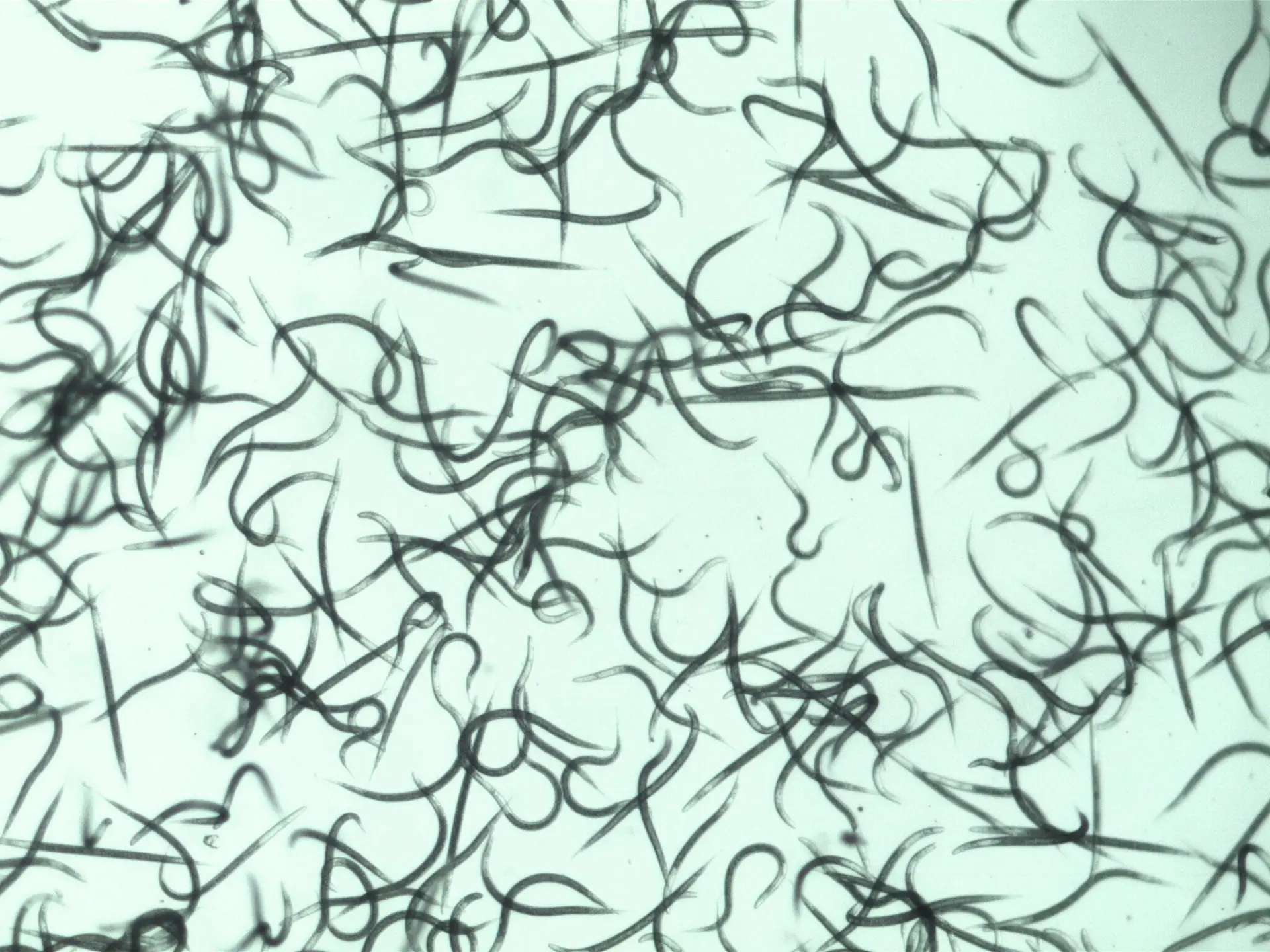

- A novel ICAR-SBI EPN biopesticide formulation was developed first of its kind with longer shelf life of 6-7 months for Heterorhabditis and 9 to 12 months for Steinernema spp..

- EPN Technology is an Eco-friendly safe biocontrol method for white grubs control in not only in sugarcane but in other several economically important crops.

- Successful control of white grubs (more than 75%) recorded with EPN application under field conditions

- The ICAR-SBI EPN Biopesticide formulation technology has been commercialized (Coordinated by AGRINNOVATE India, New Delhi) with a license fee of 2 lakhs per company and Licensed to 16 biopesticide companies across the country.

- A total revenue of Rs 33 lakhs has been generated through ICAR SBI EPN Biopesticide formulation.

- Ranked in top 10 Technology Licensed by Agrinnovate India New Delhi during 2022

- More than 400 tonnes of EPN formulation has been produced & marketed by our Licensee companies which has covered more than 2.25 lakh acre benefitting several farmers across several crops and states of India

- ICAR SBI EPN Biopesticide Formulation Technology was released by Shri Narendra Singh Tomar, Hon’ble Union Minister of Agriculture & Farmers welfare, Shri Parshottam Rupala, Hon’ble Union Minister of Fisheries, Animal Husbandry & Dairying and Shri Kailash Choudhary, Hon’ble Union Minister of state for Agriculture & Farmers welfare during ICAR’S 93rd Annual General Body Meeting held at NASC, New Delhi on 26.03.2022